Parts of a Trebuchet

Parts of a Trebuchet

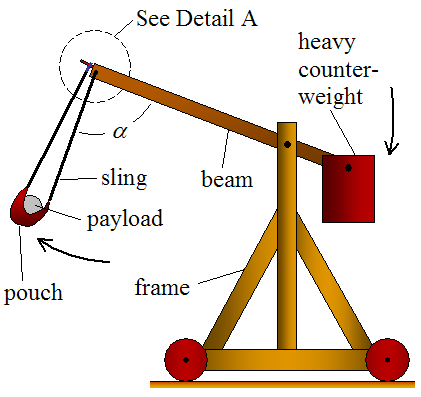

The trebuchet is an extraordinary machine that combines simplicity and ingenuity to achieve remarkable results. At its heart lies the beam, which serves as the primary lever responsible for amplifying force and transferring energy from the counterweight to the projectile. This long, sturdy component is typically constructed from durable materials such as wood or metal, depending on the size and intended use of the trebuchet. The beam's length plays a crucial role in determining the range and power of the weapon. A longer beam increases the mechanical advantage, allowing the trebuchet to hurl projectiles over greater distances with increased accuracy.

When designing a trebuchet, careful consideration must be given to the beam's balance point. Ideally, the beam should pivot around a central axis, dividing it into two distinct sections: one shorter section connected to the counterweight and another longer section attached to the sling. This arrangement ensures that the downward motion of the counterweight generates sufficient rotational force to propel the projectile forward. Additionally, the material and weight distribution along the beam influence its performance. For instance, using lighter materials for the longer end reduces inertia, enabling faster acceleration and improving overall efficiency.

To maximize the effectiveness of the trebuchet, the beam must also be properly aligned with other components, such as the frame and guides. Misalignment can lead to uneven movement, reducing the machine's accuracy and potentially causing structural damage. Proper maintenance of the beam is equally important, as wear and tear over time may compromise its strength and stability. Regular inspections and repairs are essential to ensure the trebuchet remains operational and reliable during prolonged use.

Beam Design Considerations

Material Selection

Choosing the right material for the beam is vital for constructing a functional trebuchet. Historically, wood was the most common choice due to its abundance, ease of shaping, and favorable strength-to-weight ratio. However, modern builders often experiment with metals like aluminum or steel to enhance durability and reduce weight. Each material has its advantages and disadvantages; for example, wooden beams are more forgiving when subjected to stress but require regular upkeep to prevent rot or cracking. On the other hand, metal beams offer superior longevity but may add unnecessary bulk if improperly designed.

Length and Weight Distribution

The optimal length of the beam depends on the specific requirements of the trebuchet. Longer beams generally provide better leverage, enabling the trebuchet to launch heavier projectiles farther. However, excessively long beams can become unwieldy and prone to flexing under load, which negatively impacts performance. Similarly, the distribution of weight along the beam affects its ability to transfer energy efficiently. Placing the center of gravity closer to the pivot point improves stability but may slightly reduce the range. Conversely, shifting the center of gravity toward the longer end enhances distance but risks compromising structural integrity.

Maintenance Tips

Regular maintenance is key to preserving the beam's functionality. For wooden beams, applying protective coatings such as varnish or linseed oil helps shield against moisture and decay. Metal beams should be inspected periodically for signs of corrosion or fatigue, with any damaged areas promptly repaired or replaced. Lubricating moving parts near the pivot point minimizes friction and prolongs the life of the beam. By adhering to these practices, builders can ensure their trebuchets remain effective tools for years to come.

Pivot

The pivot is another critical component of the trebuchet, serving as the fulcrum around which the entire mechanism rotates. It functions as the balancing point between the two ends of the beam, facilitating smooth and controlled movement during operation. Typically constructed from strong, durable materials such as iron or steel, the pivot must withstand significant forces without deforming or failing. Its design directly influences the trebuchet's performance, making it one of the most important elements to consider during construction.

A well-designed pivot allows the beam to rotate freely while maintaining precise alignment with the rest of the trebuchet. This ensures consistent and predictable behavior, which is essential for achieving accurate launches. In some designs, bearings or bushings are incorporated into the pivot assembly to reduce friction and improve efficiency. These additional components help minimize wear and extend the lifespan of the trebuchet by distributing stress more evenly across the structure.

Proper installation of the pivot is equally important for ensuring reliable operation. It should be securely anchored to the frame, with all connections tightened to specification. Any looseness or misalignment could result in erratic movement, leading to reduced accuracy and potential damage to surrounding components. Furthermore, the pivot's height relative to the ground affects the trajectory of the projectile. Adjustments to this parameter allow operators to fine-tune the trebuchet's performance based on specific targets or environmental conditions.

Types of Pivots

Fixed vs. Floating Pivots

There are two main types of pivots used in trebuchets: fixed and floating. A fixed pivot remains stationary throughout the launch cycle, providing stable support for the beam. While simpler to construct, fixed pivots may generate higher levels of friction compared to their floating counterparts. Floating pivots, on the other hand, allow limited movement within a defined range, helping to absorb shocks and maintain equilibrium during operation. This flexibility often results in smoother launches and improved accuracy, albeit at the cost of added complexity.

Bearings and Bushings

Incorporating bearings or bushings into the pivot assembly offers several benefits, including reduced friction and enhanced durability. Ball bearings, for example, enable the beam to rotate with minimal resistance, allowing for faster acceleration and greater efficiency. Sleeve bearings or bushings provide similar advantages while being easier to install and maintain. Regardless of the type chosen, proper lubrication is essential to ensure optimal performance and prevent premature wear.

Maintenance Recommendations

Maintaining the pivot is crucial for sustaining the trebuchet's reliability and effectiveness. Regular cleaning and lubrication help keep moving parts functioning smoothly, while periodic inspections identify potential issues before they escalate. Replacing worn-out components promptly prevents further damage and ensures consistent performance. By following these guidelines, operators can maximize the lifespan of their trebuchets and enjoy reliable service for extended periods.

Sling

The sling is a vital component of the trebuchet, responsible for holding the projectile during the launch sequence. Attached to the longer end of the beam, the sling consists of a pouch connected to two ropes or cords of equal length. As the beam swings upward, the tension in the ropes causes the pouch to release the projectile at just the right moment, maximizing both distance and accuracy. The design and construction of the sling play a significant role in determining the trebuchet's overall effectiveness.

Selecting appropriate materials for the sling is paramount for ensuring its durability and performance. Traditionally, natural fibers such as hemp or linen were favored for their strength and flexibility. Modern alternatives include synthetic materials like nylon or polyester, which offer superior resistance to weathering and abrasion. Regardless of the material chosen, the sling must be able to withstand repeated cycles of tension and release without tearing or losing elasticity.

Proper adjustment of the sling's length and attachment points is equally important for achieving optimal results. Altering these parameters allows operators to fine-tune the trebuchet's performance, compensating for variations in projectile size, weight, or desired trajectory. For example, shortening the sling increases the angle of release, resulting in a higher arc, while lengthening it produces a flatter trajectory suitable for targeting distant objects.

Sling Construction Techniques

Choosing the Right Materials

When building a sling, selecting high-quality materials is essential for ensuring longevity and reliability. Natural fibers like hemp provide excellent tensile strength and flexibility, making them ideal for traditional applications. Synthetic options such as nylon or polyester offer additional benefits, including resistance to UV radiation and moisture, which can degrade natural fibers over time. Mixing different materials can yield hybrid slings that combine the best qualities of each, providing enhanced performance under various conditions.

Attaching the Pouch

The pouch portion of the sling must be securely fastened to the ropes or cords to prevent accidental detachment during operation. Common methods include sewing, weaving, or tying knots, each offering unique advantages depending on the materials used. Ensuring even tension between the two attachment points is critical for maintaining balance and preventing premature release of the projectile. Testing the connection thoroughly prior to deployment helps identify potential weaknesses and ensures safe operation.

Tuning the Sling

Adjusting the sling's length and orientation is a key aspect of optimizing trebuchet performance. Operators can experiment with different configurations to find the ideal settings for their specific needs. Marking reference points on the ropes facilitates quick adjustments during field operations, allowing for rapid recalibration as needed. Careful attention to detail during this process ensures consistent results and maximizes the trebuchet's capabilities.

Pouch

The pouch serves as the container for the projectile during the launch sequence, playing a crucial role in determining the trebuchet's accuracy and effectiveness. Typically crafted from durable materials such as leather or canvas, the pouch must be strong enough to hold the projectile securely while remaining flexible enough to release it cleanly at the appropriate moment. Its design directly impacts the trajectory and velocity of the launched object, making it one of the most important components to consider during construction.

The shape and size of the pouch depend largely on the type of projectile being used. Larger, heavier projectiles require sturdier pouches capable of withstanding greater forces without tearing or deforming. Smaller, lighter projectiles demand more precise control, necessitating carefully tailored dimensions to ensure proper alignment and release. Properly sizing the pouch ensures maximum energy transfer from the trebuchet to the projectile, resulting in improved range and accuracy.

Material selection also plays a significant role in the pouch's performance. Leather, for example, provides excellent durability and flexibility, making it a popular choice for traditional trebuchets. Canvas offers similar benefits while being easier to work with and less expensive. Modern builders sometimes opt for synthetic materials like Kevlar or ballistic nylon, which combine exceptional strength with lightweight properties. Regardless of the material chosen, reinforcing seams and stress points is essential for preventing failure during operation.

Customizing the Pouch

Shape and Size Adjustments

Customizing the pouch's shape and size according to the projectile's characteristics is vital for achieving optimal results. For irregularly shaped objects, creating a custom-fitted pouch ensures secure containment and smooth release. Rounded or spherical projectiles benefit from slightly oversized pouches, allowing for slight movement during launch without compromising stability. Experimenting with different configurations helps identify the best solution for specific applications.

Reinforcement Techniques

Reinforcing the pouch is crucial for extending its lifespan and preventing catastrophic failures during operation. Adding extra layers of material at stress points, such as the corners or attachment areas, strengthens the structure without significantly increasing weight. Using reinforced stitching or bonding agents further enhances durability, ensuring the pouch remains intact even after repeated use. Regular inspections and timely repairs help mitigate risks associated with wear and tear.

Practical Advice for Builders

Building a functional pouch requires careful planning and execution. Start by selecting appropriate materials based on the intended application and expected loads. Cut patterns accurately to ensure proper fit and function, paying close attention to seam allowances and edge finishes. Test the completed pouch thoroughly under simulated launch conditions to verify its performance and make necessary adjustments before deploying it in real-world scenarios.

Projectile

The projectile is the object launched by the trebuchet, representing the culmination of all the machine's efforts. Its size, shape, weight, and composition greatly influence the trebuchet's effectiveness, making it a critical factor in determining success on the battlefield or in competitive events. Projectiles can vary widely in design, ranging from simple stones or metal balls to complex incendiary devices or specialized munitions. Understanding how different projectiles interact with the trebuchet's mechanics is essential for optimizing performance.

Choosing the right projectile involves balancing several competing factors, including range, accuracy, and impact force. Heavier projectiles tend to travel shorter distances but deliver greater striking power upon impact. Lighter projectiles, conversely, achieve longer ranges but may lack sufficient force to cause significant damage. The shape of the projectile also affects its aerodynamics, influencing both trajectory and terminal velocity. Streamlined designs reduce air resistance, allowing for smoother flight paths and improved accuracy.

Safety considerations must always take precedence when selecting projectiles. Using inappropriate materials or improper handling techniques can pose serious risks to operators and bystanders alike. Always adhere to established guidelines and regulations governing the use of trebuchets and related equipment. Conduct thorough risk assessments prior to launching any projectile, ensuring all necessary precautions are in place to protect personnel and property.

Selecting the Ideal Projectile

Balancing Range and Impact

Determining the optimal balance between range and impact depends on the specific goals of the operation. For military applications, prioritizing impact force might be more important than achieving maximum distance. In recreational settings, however, emphasizing range and accuracy could enhance enjoyment and competitiveness. Experimenting with various projectile types under controlled conditions helps identify the best options for particular situations.

Aerodynamic Enhancements

Improving the aerodynamic properties of projectiles can significantly enhance trebuchet performance. Incorporating features such as fins or stabilizers reduces drag and promotes stable flight, increasing both range and precision. Using lightweight yet dense materials minimizes air resistance while maintaining sufficient mass for effective impact. Innovations in projectile design continue to push the boundaries of what trebuchets can accomplish, inspiring new generations of enthusiasts and engineers alike.

Safety Protocols

Prioritizing safety when working with projectiles cannot be overstated. Always follow recommended procedures for loading, aiming, and firing the trebuchet to minimize hazards. Wear appropriate personal protective equipment (PPE) during operations, and establish clear communication protocols among team members to avoid misunderstandings. Regularly review and update safety plans as needed to address emerging concerns and ensure continued compliance with industry standards.

Detailed Checklist for Building a Trebuchet

To successfully build a functional trebuchet, follow this comprehensive checklist step-by-step:

Gather Materials: Acquire all necessary materials, including wood, metal, rope, leather, and any specialized components required for your design. Ensure you have adequate quantities of each item to complete the project without interruptions.

- Actionable Step: Create a detailed list of materials beforehand and verify availability before starting construction.

Design the Frame: Develop a blueprint or schematic detailing the dimensions and layout of the trebuchet's frame. Focus on creating a stable base capable of supporting the machine's weight and absorbing recoil during operation.

- Actionable Step: Use computer-aided design (CAD) software or sketch templates by hand to visualize the final product and plan accordingly.

Construct the Beam: Build the beam according to specifications, paying close attention to length, weight distribution, and material selection. Ensure it is balanced correctly and securely mounted to the pivot point.

- Actionable Step: Test the beam's balance and adjust as needed to achieve optimal performance.

Install the Pivot: Attach the pivot to the frame, ensuring it is firmly secured and aligned properly. Incorporate bearings or bushings if desired to reduce friction and improve efficiency.

- Actionable Step: Lubricate all moving parts regularly to maintain smooth operation and prevent wear.

Assemble the Sling: Fabricate the sling using durable materials and attach it securely to the beam. Adjust its length and orientation to suit your intended projectiles and target trajectories.

- Actionable Step: Perform trial launches with dummy payloads to evaluate sling performance and make necessary adjustments.

Prepare the Pouch: Craft the pouch to match the size and shape of your chosen projectiles. Reinforce critical areas to enhance durability and prevent failure during use.

- Actionable Step: Inspect the pouch frequently for signs of damage or wear, replacing it promptly if issues arise.

Add Counterweight: Construct or acquire a suitable counterweight, ensuring it is heavy enough to generate sufficient force while remaining manageable during setup and teardown.

- Actionable Step: Secure the counterweight firmly to prevent accidental dislodging during operation.

Calibrate the Guides: Install guides along the beam's path to maintain alignment and promote consistent movement. Fine-tune their positioning as needed to optimize performance.

- Actionable Step: Monitor guide performance during test launches and make adjustments as required.

Set Up the Trip Mechanism: Integrate a reliable trip mechanism or trigger system to control the release of the sling at precisely the right moment. Practice operating it repeatedly to develop proficiency.

- Actionable Step: Train all operators thoroughly in the safe and correct usage of the trip mechanism.

Test and Refine: Conduct extensive testing of the completed trebuchet, documenting results and identifying areas for improvement. Make incremental changes to refine performance until satisfied with the outcome.

- Actionable Step: Keep detailed records of each test session, noting variables such as weather conditions, projectile type, and observed behaviors.

By meticulously following this checklist, aspiring trebuchet builders can construct robust, efficient machines capable of delivering impressive results. Remember that patience and persistence are key to mastering the art of trebuchet engineering—happy building!

Deja una respuesta