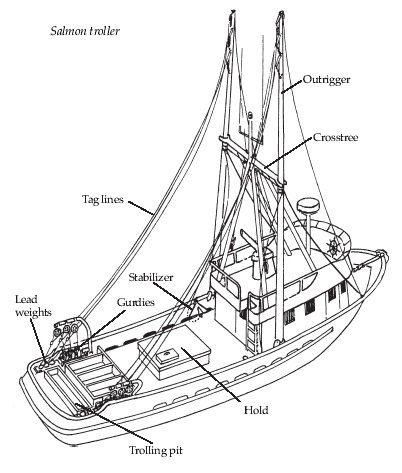

Parts of a Commercial Salmon Fishing Boat

Parts of a Commercial Salmon Fishing Boat

Commercial salmon fishing boats are meticulously designed vessels that play a vital role in the global seafood industry. These boats are engineered to withstand harsh marine environments while ensuring efficiency and sustainability in capturing and processing salmon. Understanding the various parts of such a vessel is essential for anyone interested in the intricacies of commercial fishing. In this section, we will delve into the deck, which serves as the primary working area where much of the fishing activity takes place.

The deck of a commercial salmon fishing boat is more than just a flat surface; it is the heart of operations. Fishermen spend most of their time here, operating gear, handling the catch, and maintaining equipment. The deck is typically spacious to accommodate the necessary tools and machinery required for fishing. It is also designed with safety in mind, featuring non-slip surfaces and secure railings to prevent accidents in rough seas. Additionally, the deck may include specialized areas for sorting and processing fish, making it a multifunctional space.

One of the key features of the deck is its ability to adapt to different fishing techniques. Depending on whether the boat uses nets, lines, or traps, the layout of the deck can vary significantly. For example, boats using trawl nets often have large winches mounted on the deck to deploy and retrieve the heavy gear. Similarly, longline fishing vessels may have dedicated stations for baiting hooks and hauling in lines. This flexibility ensures that the deck remains an efficient workspace regardless of the fishing method employed.

Safety is paramount on the deck, and modern commercial fishing boats incorporate numerous measures to protect crew members. For instance, many decks are equipped with hydraulic systems that automate tasks such as lifting heavy loads, reducing the risk of injury. Furthermore, emergency equipment like life rafts and fire extinguishers are strategically placed for quick access. By prioritizing both functionality and safety, the deck becomes a crucial component of the fishing operation.

Deck Maintenance Checklist

To ensure the deck remains in optimal condition, fishermen should follow this detailed checklist:

- Regular Cleaning: Sweep and wash the deck daily to remove debris and prevent slippery conditions. Use freshwater if possible to avoid salt buildup.

- Inspect Non-Slip Surfaces: Check for wear and tear on non-slip coatings and repair any damaged areas promptly.

- Secure Equipment: Ensure all tools and machinery are properly secured when not in use to prevent them from shifting during rough weather.

- Test Hydraulic Systems: Regularly test hydraulic systems for leaks or malfunctions and address issues immediately.

- Check Railings and Guardrails: Inspect railings and guardrails for stability and replace any weakened components.

- Verify Emergency Gear Placement: Confirm that emergency gear is easily accessible and functional at all times.

By adhering to this checklist, fishermen can maintain a safe and efficient working environment on the deck.

Wheelhouse

The wheelhouse is another critical component of a commercial salmon fishing boat, serving as the command center for navigation and communication. Positioned high above the deck, the wheelhouse provides the captain with unobstructed views of the surrounding waters, allowing for precise steering and decision-making. Inside, the wheelhouse houses a variety of advanced instruments, including GPS systems, radar screens, and radios, which facilitate safe and effective navigation.

Modern wheelhouses are designed with ergonomics in mind, offering comfortable seating and easy access to controls. This helps reduce fatigue for the captain and crew during long voyages. Additionally, the wheelhouse is often insulated to minimize noise from the engine and protect occupants from extreme weather conditions. Such features enhance the overall experience of operating the vessel, ensuring that the captain can focus on the task at hand without unnecessary distractions.

Communication is a cornerstone of successful fishing operations, and the wheelhouse plays a pivotal role in this regard. Equipped with state-of-the-art radios, the wheelhouse enables the captain to stay in contact with other vessels, shore bases, and regulatory authorities. This connectivity is particularly important in emergencies, where timely communication can make all the difference. Moreover, the wheelhouse often includes satellite phones for situations where traditional radio signals are unavailable.

Wheelhouse Optimization Tips

To maximize the effectiveness of the wheelhouse, consider these actionable steps:

- Organize Instruments: Arrange navigation and communication instruments in a logical manner to allow quick access during critical moments.

- Update Software: Regularly update GPS and radar software to ensure accuracy and reliability.

- Train Crew Members: Provide training for all crew members on how to operate wheelhouse equipment in case of emergencies.

- Conduct Routine Inspections: Perform regular checks on all instruments and systems to identify potential issues early.

- Enhance Visibility: Keep windows clean and free of obstructions to maintain clear visibility at all times.

- Invest in Backup Systems: Install backup power sources and communication devices to prepare for unexpected failures.

By implementing these tips, captains can ensure that the wheelhouse remains a reliable hub for navigation and communication.

Hold

The hold is one of the most important sections of a commercial salmon fishing boat, as it is responsible for storing the catch. Designed to maximize storage capacity while maintaining the quality of the salmon, the hold is typically located below the deck and spans a significant portion of the vessel's interior. Many holds are equipped with refrigeration units to preserve the fish during long voyages, ensuring that they remain fresh until they reach the market.

Refrigeration systems in the hold are a marvel of engineering, capable of maintaining consistent temperatures even in the harshest ocean conditions. These systems often use advanced insulation materials to minimize energy consumption while maximizing cooling efficiency. Some vessels employ ice-based systems, where large quantities of ice are stored and used to chill the hold. Regardless of the method, the goal is always to keep the salmon in pristine condition, which is crucial for maintaining market value.

Maintaining the cleanliness and organization of the hold is equally important. Fishermen must regularly clean the hold to prevent contamination and odors. Proper organization within the hold also helps optimize space usage and simplifies the process of loading and unloading the catch. By paying attention to these details, crews can ensure that the hold functions effectively throughout the fishing season.

Hold Maintenance Guidelines

Here’s a comprehensive checklist to maintain the hold:

- Clean After Each Trip: Thoroughly clean the hold after every voyage to eliminate any lingering smells or residue.

- Inspect Refrigeration Units: Regularly check refrigeration systems for leaks or malfunctions and schedule routine maintenance.

- Organize Storage: Use bins or racks to organize the catch and maximize available space.

- Monitor Temperature: Continuously monitor the temperature inside the hold to ensure it remains within the desired range.

- Prevent Water Accumulation: Drain any water that accumulates in the hold to prevent spoilage and damage.

- Stock Adequate Supplies: Keep spare parts and cleaning supplies readily available for emergencies.

Following these guidelines will help ensure that the hold remains a safe and efficient storage area for the salmon catch.

Winches and Reels

Winches and reels are indispensable tools on commercial salmon fishing boats, enabling fishermen to deploy and retrieve their gear with ease. These mechanical systems are designed to handle the immense forces exerted by heavy fishing nets, lines, and traps. By automating these labor-intensive tasks, winches and reels significantly reduce the physical strain on crew members, allowing them to focus on other aspects of the operation.

The design of winches and reels varies depending on the specific fishing technique being used. For example, trawl net operations require robust winches capable of pulling thousands of pounds of gear through the water. In contrast, longline fishing relies on smaller, more precise reels for managing individual lines. Despite these differences, all winches and reels share common features such as sturdy construction, smooth operation, and durability in saltwater environments.

Proper maintenance of winches and reels is essential to ensure their longevity and performance. Regular lubrication of moving parts helps prevent corrosion and extends the lifespan of the equipment. Additionally, periodic inspections can identify potential issues before they lead to costly breakdowns. By investing time and effort into maintaining these systems, fishermen can avoid delays and ensure smooth operations.

Winch and Reel Maintenance Checklist

To keep winches and reels functioning optimally, adhere to this checklist:

- Lubricate Moving Parts: Apply appropriate lubricants to gears, bearings, and cables to reduce friction and prevent rust.

- Inspect Cables and Lines: Check for signs of wear or damage on cables and lines and replace them as needed.

- Test Brake Systems: Verify that brake systems are functioning correctly to prevent accidental deployment of gear.

- Clean Regularly: Remove saltwater residue and debris from winches and reels to prevent clogging.

- Store Properly: When not in use, cover winches and reels to protect them from the elements.

- Schedule Professional Inspections: Have a qualified technician inspect the systems annually to identify hidden problems.

By following these steps, fishermen can ensure that their winches and reels remain reliable and efficient.

Sonar and Radar Systems

Sonar and radar systems are sophisticated technologies that greatly enhance the capabilities of commercial salmon fishing boats. These systems enable fishermen to locate schools of salmon with remarkable precision, improving the efficiency of their operations. Sonar works by emitting sound waves that bounce off objects underwater, creating a detailed image of the seabed and any nearby fish. Radar, on the other hand, uses radio waves to detect obstacles and other vessels, ensuring safe navigation even in poor visibility conditions.

Modern sonar systems offer features such as 3D imaging and real-time data analysis, providing fishermen with valuable insights into the behavior and movement of salmon. This information allows crews to adjust their fishing strategies dynamically, increasing their chances of success. Similarly, radar systems provide critical data about the surrounding environment, helping captains avoid collisions and navigate safely through crowded waters.

Both sonar and radar systems require careful calibration and maintenance to function effectively. Misaligned sensors or outdated software can lead to inaccurate readings, potentially compromising the entire operation. Therefore, it is essential for crews to regularly update and test these systems to ensure their reliability.

Sonar and Radar Maintenance Recommendations

To maintain sonar and radar systems, follow these practical steps:

- Calibrate Sensors: Periodically recalibrate sensors to ensure accurate readings.

- Update Software: Keep software up-to-date to take advantage of new features and improvements.

- Inspect Antennas: Check antennas for damage or misalignment and repair as necessary.

- Test Systems Regularly: Conduct routine tests to verify that both sonar and radar systems are functioning correctly.

- Protect Against Corrosion: Apply protective coatings to exposed components to prevent saltwater corrosion.

- Consult Manufacturer Guidelines: Refer to manufacturer manuals for specific maintenance instructions.

By adhering to these recommendations, fishermen can ensure that their sonar and radar systems remain accurate and dependable.

Hull

The hull of a commercial salmon fishing boat is its structural backbone, providing both buoyancy and stability in challenging marine environments. Engineered with precision, the hull is designed to withstand the rigors of open ocean fishing while minimizing drag and maximizing fuel efficiency. Its shape and composition play a critical role in determining the vessel's performance, influencing factors such as speed, maneuverability, and load capacity.

Modern hull designs incorporate advanced materials and construction techniques to enhance durability and reduce maintenance requirements. For example, many commercial fishing boats feature fiberglass or aluminum hulls, which offer excellent resistance to corrosion and impact. Additionally, some vessels employ hydrodynamic designs that improve stability in rough seas, giving fishermen greater confidence when venturing far from shore.

Routine maintenance of the hull is essential to prolong its lifespan and ensure the safety of the crew. Regular inspections can reveal minor issues before they escalate into major problems. Tasks such as painting the hull to prevent barnacle growth and checking for cracks or leaks are simple yet crucial steps in maintaining the integrity of the vessel.

Hull Maintenance Procedures

To keep the hull in top condition, follow this detailed checklist:

- Inspect for Damage: Regularly examine the hull for cracks, dents, or signs of corrosion and repair them promptly.

- Apply Anti-Fouling Paint: Use anti-fouling paint to prevent marine organisms from attaching to the hull, which can increase drag.

- Check Seals and Gaskets: Ensure that all seals and gaskets are intact to prevent water ingress.

- Clean Regularly: Wash the hull frequently to remove salt deposits and algae buildup.

- Monitor Ballast Tanks: Inspect ballast tanks for leaks or corrosion and maintain proper water levels to ensure stability.

- Schedule Professional Inspections: Have a professional marine surveyor inspect the hull annually for thorough evaluations.

By following these procedures, fishermen can ensure that their vessel remains seaworthy and reliable.

Engine Compartment

The engine compartment houses the powerful engines that propel commercial salmon fishing boats through the water. These engines are the lifeline of the vessel, providing the energy needed for navigation, fishing operations, and auxiliary systems. Modern fishing boats often feature diesel engines due to their efficiency, reliability, and ability to generate substantial power. However, maintaining these engines requires diligence and expertise to ensure they operate smoothly under demanding conditions.

Engine compartments are designed to provide easy access to critical components, facilitating routine maintenance and repairs. They also include safety features such as fire suppression systems and ventilation fans to mitigate risks associated with fuel combustion. Proper ventilation is especially important, as it prevents the buildup of harmful gases and reduces the likelihood of overheating.

Effective engine maintenance is key to extending the lifespan of the vessel and minimizing downtime. Regular oil changes, filter replacements, and system checks are just a few of the tasks that contribute to engine longevity. Additionally, monitoring fuel consumption and emissions can help identify potential issues before they become serious problems.

Engine Compartment Maintenance Checklist

To maintain the engine compartment, follow this comprehensive checklist:

- Change Oil and Filters: Replace engine oil and filters according to the manufacturer's recommendations.

- Inspect Belts and Hoses: Check belts and hoses for signs of wear or cracking and replace them as needed.

- Test Cooling Systems: Verify that cooling systems are functioning properly to prevent overheating.

- Clean the Compartment: Keep the engine compartment clean and free of debris to reduce fire hazards.

- Monitor Fuel Quality: Regularly test fuel for contaminants and treat it with additives if necessary.

- Schedule Professional Servicing: Have a certified technician service the engine at least once a year for thorough inspections.

By adhering to this checklist, fishermen can ensure that their engines remain powerful and dependable, supporting the vessel's overall performance.

In summary, each part of a commercial salmon fishing boat plays a vital role in its operation, from the deck where the action unfolds to the engine compartment that powers the vessel forward. By understanding and maintaining these components, fishermen can achieve greater efficiency, safety, and success in their endeavors.

Deja una respuesta