Parts of a Water Softener

Parts of a Water Softener

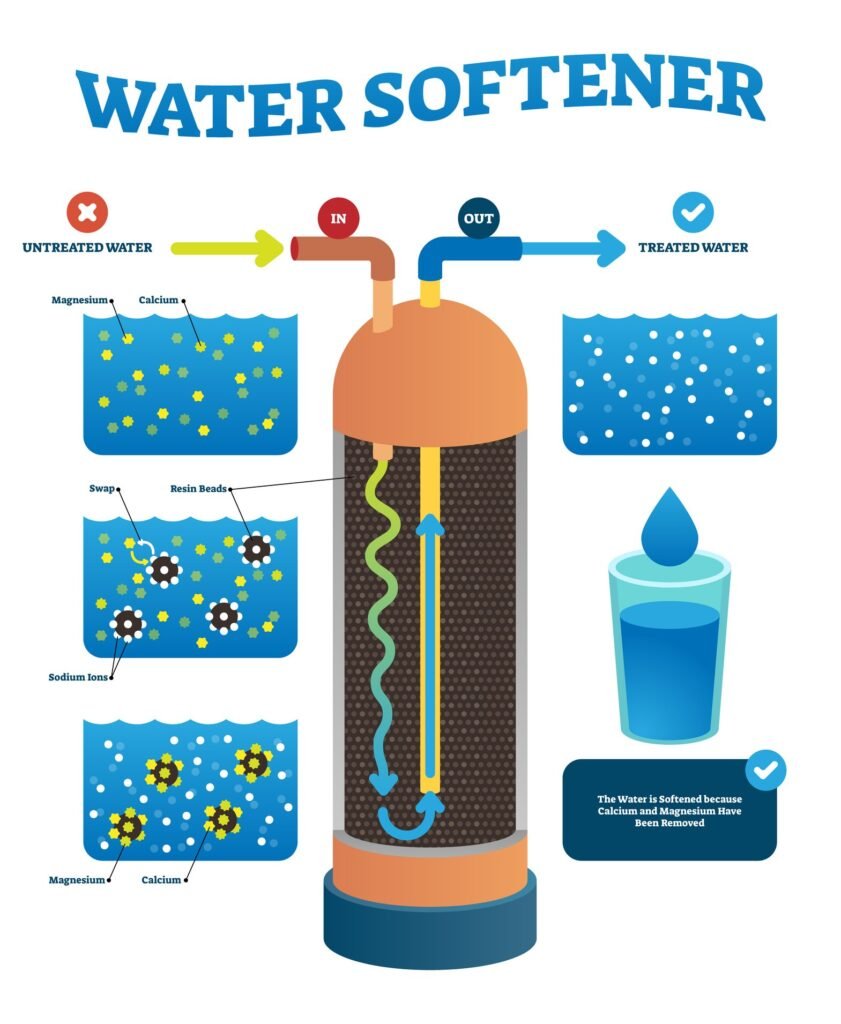

A water softener is an essential device for households dealing with hard water issues. Hard water, rich in calcium and magnesium, can lead to numerous problems, such as scale buildup in pipes, reduced appliance efficiency, and difficulty in cleaning. Understanding the parts of a water softener is crucial for anyone considering installing or maintaining one. These systems consist of several key components that work together seamlessly to remove hardness minerals from water and improve its quality.

The primary function of a water softener is to soften water by removing calcium and magnesium ions through a process called ion exchange. This involves specialized resin beads housed within the resin tank. These beads attract and hold onto the hard water minerals, effectively replacing them with sodium or potassium ions. Let’s delve deeper into the various components that make up a water softener and how they contribute to its functionality.

Resin Tank

The resin tank is the heart of any water softener system. It houses the resin beads, which are small, spherical structures made of polystyrene or similar materials. These beads are coated with a special resin that facilitates the ion exchange process. When hard water flows through the resin tank, the resin beads attract calcium and magnesium ions, effectively trapping them while releasing sodium or potassium ions into the water. This exchange results in softened water that is much easier to use for cleaning, bathing, and other household activities.

One important aspect of the resin tank is its durability. The beads inside can last for many years before needing replacement, provided they are properly maintained. Over time, however, the resin beads lose their effectiveness as they become saturated with hard water minerals. To restore their capacity, a regeneration cycle is necessary, which we will discuss in detail later. Proper maintenance of the resin tank ensures that the water softener continues to operate efficiently and effectively.

In addition to housing the resin beads, the resin tank also plays a role in filtering out sediment and impurities from the water. While the primary purpose of the resin tank is ion exchange, it indirectly contributes to overall water quality improvement by ensuring that only clean, softened water enters your home's plumbing system. Regular inspection and cleaning of the resin tank are essential to prevent clogging and ensure optimal performance.

Ion Exchange Process

The ion exchange process is the cornerstone of how water softeners function. This process involves the swapping of ions between the hard water minerals (calcium and magnesium) and the sodium or potassium ions present on the resin beads. When water containing these hard minerals passes through the resin tank, the resin beads attract the positively charged calcium and magnesium ions due to their higher affinity for these minerals compared to sodium or potassium.

This attraction causes the hard water ions to adhere to the surface of the resin beads, displacing the sodium or potassium ions into the water. As a result, the water exiting the resin tank is free of calcium and magnesium, making it softer and more suitable for household use. The ion exchange process is highly efficient and ensures that even large volumes of water can be softened consistently.

It is worth noting that the ion exchange process does not remove all contaminants from the water. While it effectively reduces hardness, it does not address issues like chlorine, bacteria, or other dissolved solids. For comprehensive water treatment, additional filtration systems may be required. However, for most households, the ion exchange process provides sufficient benefits to justify the installation of a water softener.

Another critical factor to consider is the type of ions used in the exchange process. Traditionally, sodium ions are used, but some modern systems utilize potassium ions instead. Potassium-based systems are often preferred by individuals on low-sodium diets or those concerned about the environmental impact of sodium discharge. Regardless of the ion type, the ion exchange process remains a reliable and effective method for softening water.

Brine Tank

The brine tank is another essential component of a water softener system. Its primary role is to store salt or potassium pellets, which are used during the regeneration cycle to recharge the resin beads. The brine tank typically sits adjacent to the resin tank and is connected via a brine line. During the regeneration process, a concentrated solution of saltwater or potassium water is drawn from the brine tank and flushed through the resin tank, restoring the beads' ability to attract hard water minerals.

Maintaining the brine tank is relatively straightforward but requires regular attention. Salt or potassium pellets need to be replenished periodically to ensure that the regeneration cycle can occur as needed. The frequency of refilling depends on factors such as water usage, the hardness level of the incoming water, and the capacity of the water softener. Most manufacturers provide guidelines for determining when to add more pellets, often based on the number of days since the last refill.

It is important to choose the right type of salt or potassium pellets for your system. High-quality pellets dissolve more completely, reducing the risk of clogging and ensuring efficient operation. Some users prefer food-grade salts or potassium chloride for environmental or health reasons. Regardless of the choice, proper maintenance of the brine tank is vital to prevent issues such as bridging, where the pellets form a hardened layer that prevents water from reaching them.

Salt or Potassium Pellets

The choice between salt or potassium pellets depends on personal preferences and specific needs. Sodium-based pellets are more commonly used because they are generally less expensive and widely available. They are effective in regenerating the resin beads and maintaining the water softener's performance. However, some homeowners opt for potassium-based systems due to concerns about sodium intake or environmental impact.

Potassium pellets offer a healthier alternative for individuals who need to monitor their sodium consumption. Additionally, potassium-based systems are considered more environmentally friendly because they do not contribute to increased sodium levels in wastewater. On the downside, potassium pellets tend to be more expensive than their sodium counterparts and may require more frequent refills due to their lower density.

When selecting pellets, it is important to consider factors such as cost, availability, and compatibility with your water softener model. Always refer to the manufacturer's recommendations to ensure optimal performance and longevity of your system.

Regeneration Cycle

The regeneration cycle is a critical process that restores the resin beads' ability to soften water after they have become saturated with hard water minerals. This cycle typically occurs during off-peak hours, such as late at night, to minimize disruptions to household water usage. The process involves several steps, including backwashing, regeneration, and rinsing.

During the backwash phase, water is flushed backward through the resin tank to loosen any trapped particles and redistribute the resin bed. This step helps maintain the efficiency of the ion exchange process by ensuring that the beads remain evenly distributed and free of debris. Following the backwash, the regeneration phase begins, during which a concentrated brine solution is drawn from the brine tank and passed through the resin tank. This solution recharges the resin beads by replacing the trapped calcium and magnesium ions with sodium or potassium ions.

Finally, the rinse phase removes any remaining brine solution from the resin tank, ensuring that only softened water exits the system. Proper timing and execution of the regeneration cycle are essential for maintaining consistent water softening performance. Most modern water softeners feature programmable control valves that automate this process, allowing for customization based on water usage patterns and hardness levels.

Control Valve

The control valve is the brain of the water softener system. It regulates the flow of water through the resin and brine tanks, initiating the regeneration cycle, and ensuring efficient operation. Modern control valves are highly advanced, featuring digital displays and programmable settings that allow users to customize the system's performance according to their specific needs.

One of the primary functions of the control valve is to monitor water usage and determine when the regeneration cycle should occur. By tracking the volume of water passing through the system, the control valve can accurately predict when the resin beads will become saturated and require regeneration. This capability helps optimize the system's efficiency, reducing unnecessary cycles and conserving resources.

In addition to regulating water flow, the control valve also manages the distribution of brine solution during the regeneration process. It ensures that the correct amount of brine is introduced to the resin tank, preventing overuse or underuse of salt or potassium pellets. Many control valves offer advanced features such as real-time monitoring, error alerts, and remote access via smartphone apps, providing users with greater control and convenience.

Water Flow Regulation

Effective water flow regulation is crucial for the proper functioning of a water softener. The control valve plays a central role in managing water flow, ensuring that the system operates efficiently and delivers consistent results. Proper regulation helps prevent issues such as excessive water usage, uneven distribution of softened water, and premature depletion of resin beads.

To achieve optimal water flow regulation, the control valve must be correctly calibrated and maintained. Regular inspections and adjustments are necessary to ensure that the valve operates smoothly and responds accurately to changes in water demand. Users should also be mindful of factors such as water pressure and temperature, as these can affect the system's performance.

Advanced water softeners often incorporate features such as flow meters and pressure sensors to enhance water flow regulation. These devices provide precise data on water usage patterns, enabling the control valve to make informed decisions about when to initiate the regeneration cycle. By optimizing water flow, these systems can reduce waste and improve overall efficiency, benefiting both the environment and the homeowner.

Efficient Operation

Achieving efficient operation of a water softener requires careful attention to several factors, including proper installation, regular maintenance, and smart usage practices. A well-maintained system not only delivers superior results but also extends the lifespan of the equipment, saving money in the long run.

Proper installation is the first step toward ensuring efficient operation. This involves selecting the right size and type of water softener for your home, positioning the system correctly, and connecting it securely to the plumbing system. Hiring a professional installer can help avoid common mistakes and ensure that the system meets all safety and performance standards.

Regular maintenance is equally important. Tasks such as checking the salt or potassium pellet levels, inspecting the resin tank for signs of wear, and cleaning the brine tank should be performed on a routine basis. Additionally, monitoring the system's performance and addressing any issues promptly can prevent minor problems from escalating into major repairs.

Smart usage practices, such as setting the control valve to match your household's water usage patterns, can further enhance efficiency. Many modern water softeners offer programmable settings that allow users to customize the system's operation based on factors such as time of day, season, and occupancy levels. By tailoring the system to your specific needs, you can maximize its benefits while minimizing resource consumption.

Softened Water Benefits

The benefits of using softened water in your home are numerous and significant. From improved cleaning efficiency to reduced scale buildup, softened water enhances the overall quality of life for homeowners. One of the most noticeable advantages is the reduction in soap scum and mineral deposits on surfaces, making cleaning tasks faster and easier. Softened water also helps appliances such as dishwashers and washing machines operate more efficiently, extending their lifespan and reducing energy costs.

Another key benefit of softened water is its effect on skin and hair. Hard water can leave a residue that dries out skin and dulls hair, whereas softened water rinses away soap and shampoo more thoroughly, leaving skin feeling smoother and hair shinier. Additionally, softened water improves the effectiveness of detergents and soaps, allowing you to use less product while achieving better results.

From an environmental perspective, softened water contributes to sustainability by reducing the need for harsh chemicals and excessive water usage. It also minimizes the risk of pipe corrosion and scale buildup, which can lead to costly repairs and replacements. Overall, the installation of a water softener offers a practical solution to hard water problems, providing tangible benefits that enhance comfort, convenience, and cost savings.

Detailed Checklist for Maintaining Your Water Softener

To ensure your water softener operates at peak efficiency and delivers the desired results, follow this detailed checklist:

1. Regularly Check Salt or Potassium Pellet Levels

- Action: Inspect the brine tank weekly to ensure there is an adequate supply of salt or potassium pellets.

- Why: Running out of pellets can disrupt the regeneration cycle, leading to ineffective water softening.

- How: Open the brine tank lid and visually check the pellet level. Add more pellets if the level is below the recommended mark.

2. Clean the Brine Tank Periodically

- Action: Schedule a thorough cleaning of the brine tank every three to six months.

- Why: Accumulated sediment and sludge can clog the brine line and impair the regeneration process.

- How: Remove all pellets, flush the tank with clean water, and scrub away any buildup. Refill with fresh pellets afterward.

3. Monitor Resin Tank Performance

- Action: Observe the water quality and look for signs of reduced softening effectiveness.

- Why: Saturated resin beads may fail to remove hard water minerals, resulting in poor performance.

- How: If you notice hard water symptoms, such as soap scum or scale buildup, it may be time to regenerate or replace the resin beads.

4. Calibrate the Control Valve

- Action: Adjust the control valve settings to match your household's water usage patterns.

- Why: Proper calibration ensures the regeneration cycle occurs at the optimal time, conserving resources and improving efficiency.

- How: Consult the user manual for instructions on programming the control valve. Consider factors such as daily water consumption and hardness levels.

5. Inspect the System for Leaks

- Action: Conduct a visual inspection of the water softener and surrounding areas for leaks or water damage.

- Why: Leaks can indicate loose connections or worn-out seals, potentially leading to system failure.

- How: Check all fittings, hoses, and valves for signs of moisture. Tighten or replace any damaged components as needed.

6. Test Water Hardness Levels

- Action: Use a water testing kit to measure the hardness of your softened water periodically.

- Why: Monitoring hardness levels helps verify that the water softener is functioning correctly.

- How: Follow the kit's instructions to collect a water sample and perform the test. Compare the results against the expected range for softened water.

By following this checklist diligently, you can maintain your water softener in top condition, ensuring it continues to deliver softened water that enhances your home's comfort and efficiency.

Deja una respuesta