Parts of a Fire Hydrant

Parts of a Fire Hydrant

Fire hydrants are indispensable tools for firefighters and play a pivotal role in urban safety. They are designed to provide rapid access to water during emergencies, ensuring that fires can be extinguished efficiently. Each fire hydrant consists of multiple components, each with a specific function that contributes to the overall effectiveness of the system. Understanding these parts is essential not only for firefighters but also for city planners, maintenance personnel, and anyone interested in learning about how this critical infrastructure works.

The barrel of a fire hydrant is perhaps the most visible and recognizable part. It is the upright section that extends above ground level and serves as the main body of the hydrant. This component is typically painted a bright color, such as red or yellow, to make it easily identifiable in an emergency. The barrel houses several internal mechanisms, including the valve and operating stem, which control the flow of water. Its design ensures durability and resistance to environmental factors like weather and vandalism, making it suitable for long-term outdoor use.

One of the key features of the barrel is its robust construction. Most barrels are made from materials like cast iron or ductile iron, chosen for their strength and ability to withstand high pressures. These materials also offer excellent corrosion resistance, which is crucial given the hydrant's exposure to moisture and other elements. The barrel's shape and size vary depending on local regulations and the specific needs of the area where it is installed. For instance, larger barrels may be used in industrial zones where higher water flow rates are required.

Another important aspect of the barrel is its accessibility. Firefighters need to be able to locate and operate hydrants quickly during emergencies. To facilitate this, barrels are often equipped with reflective strips or other visibility-enhancing features. Additionally, they are placed at strategic locations throughout cities and towns, ensuring that water sources are readily available wherever they might be needed. Proper placement and maintenance of the barrel are critical to ensuring that it functions correctly when called upon.

Valve

The valve is one of the most critical components inside the barrel of a fire hydrant. It controls the flow of water by opening or closing the passage between the underground water main and the hydrant's outlets. The valve is typically located near the bottom of the barrel, just above the connection to the water main. When the valve is closed, water remains trapped in the wet barrel (if applicable) or blocked off entirely in dry barrel systems. Opening the valve allows water to flow through the hydrant and out through its nozzles.

Valves in fire hydrants are designed to withstand extreme pressure conditions. They must be able to handle the force of water flowing through the system without leaking or failing. To achieve this, valves are constructed from durable materials like brass or stainless steel, which resist wear and tear over time. In addition, they are engineered to operate smoothly even after years of disuse, ensuring reliability during emergencies.

Proper maintenance of the valve is essential for the hydrant's functionality. Over time, sediment and debris can accumulate within the valve mechanism, potentially causing it to malfunction. Regular inspections and cleaning help prevent such issues, allowing the valve to open and close as intended. Fire departments and municipal authorities often have protocols in place to ensure that valves are tested periodically, guaranteeing their readiness for use.

Furthermore, the valve's operation is controlled via the operating stem, which extends upward from the valve to the surface. This stem connects to a wrench-operated handle, enabling firefighters to activate the hydrant manually. The ease with which the valve can be opened or closed depends largely on the condition of both the valve itself and the stem. Ensuring smooth movement of these components is vital for quick response times during emergencies.

Nozzles and Outlets

The nozzles or outlets of a fire hydrant are the points where hoses can be attached to draw water. These openings are strategically positioned on the sides of the barrel and come in various sizes to accommodate different types of firefighting equipment. Standard nozzle sizes include 2.5-inch and 4-inch diameters, though some hydrants may feature additional outlets for specialized applications.

Each nozzle is designed to provide a secure connection for fire hoses, preventing leaks and ensuring maximum water flow. They are typically threaded to match standard hose couplings, allowing for easy attachment and detachment. Some hydrants may also include caps or covers to protect the nozzles when not in use, shielding them from dirt, debris, and potential damage.

The placement of nozzles on a hydrant is carefully considered during its design. Ideally, they should be positioned to allow firefighters to connect hoses from multiple angles, depending on the layout of the surrounding area. This flexibility is particularly important in crowded urban environments, where space constraints may limit access to certain sides of the hydrant. By providing multiple outlet options, hydrants enable firefighters to choose the most convenient and effective approach for drawing water.

In addition to their functional role, nozzles and outlets serve as indicators of a hydrant's capacity. Larger nozzles generally correspond to higher flow rates, while smaller ones may be reserved for specific tasks or lighter-duty equipment. Understanding the capabilities of each outlet helps firefighters optimize their operations during emergencies, ensuring that they can deploy the appropriate resources for the situation at hand.

Wet Barrel vs. Dry Barrel

Hydrants can be classified into two primary types based on their internal structure: wet barrel and dry barrel. Both designs aim to deliver water effectively, but they differ significantly in terms of how they store and manage water flow.

A wet barrel hydrant contains water in the portion of the barrel that lies above ground. This means that once the valve is opened, water flows directly from the underground water main into the barrel and out through the nozzles. Wet barrel hydrants are commonly used in warmer climates where freezing temperatures are less likely to occur. Their advantage lies in their simplicity and speed of operation, as there is no need to drain the barrel after use.

On the other hand, dry barrel hydrants do not retain water in the above-ground section. Instead, they rely on a more complex system that only allows water to enter the barrel when the valve is opened. Once the hydrant is shut off, any remaining water drains back into the underground piping. This design is preferred in colder regions, as it minimizes the risk of freezing and subsequent damage to the hydrant. However, dry barrel hydrants require more intricate mechanisms, including check valves and drainage systems, to function properly.

Both types of hydrants have their own set of advantages and disadvantages. While wet barrel hydrants are easier to maintain and operate, they are less suited to areas prone to freezing. Conversely, dry barrel hydrants offer better protection against cold weather but demand more frequent inspections and repairs due to their complexity. Choosing the right type of hydrant depends on the climate, local regulations, and specific operational requirements.

Water Main and Corporal

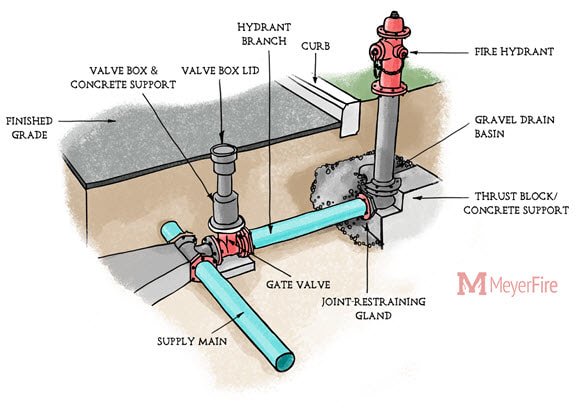

The water main is the primary source of water for a fire hydrant. It is an underground pipe that runs throughout a city or town, supplying water to homes, businesses, and public facilities. Fire hydrants tap into this network via a short connecting pipe known as the corporal. The corporal links the hydrant to the water main, providing a direct pathway for water to flow into the hydrant when needed.

Water mains are typically made from materials like PVC, ductile iron, or concrete, chosen for their durability and resistance to corrosion. These pipes are buried deep beneath the ground to protect them from external damage and temperature fluctuations. Despite their robust construction, water mains require regular maintenance to ensure they remain functional and free of leaks or blockages.

The corporal plays a crucial role in maintaining the connection between the hydrant and the water main. It must be able to withstand the pressure of water flowing through the system while also resisting environmental factors like soil erosion and chemical exposure. Corporals are usually made from materials similar to those used in the hydrant's barrel, ensuring compatibility and longevity.

Maintaining the integrity of the water main and corporal is essential for the proper functioning of fire hydrants. Any disruptions to these components could compromise the availability of water during emergencies. Municipalities often employ sophisticated monitoring systems to detect issues early and address them promptly, minimizing downtime and ensuring that hydrants remain reliable at all times.

Cap and Operating Stem

The cap of a fire hydrant serves as a protective cover for the valve mechanism. It is typically located at the top of the barrel and seals off the interior from external contaminants. Caps are designed to be tamper-resistant, preventing unauthorized access to the hydrant's internal components. They are usually secured with special tools or locks, ensuring that only trained personnel can open them.

The operating stem extends from the valve inside the barrel to the surface, where it connects to a wrench-operated handle. This stem allows firefighters to control the flow of water by turning the handle, which in turn opens or closes the valve. The stem must be strong enough to withstand the forces exerted during operation while remaining flexible enough to move smoothly.

Regular maintenance of the cap and operating stem is critical for the hydrant's performance. Over time, exposure to the elements can cause these components to corrode or seize up, making it difficult to operate the hydrant. Lubrication and cleaning are essential steps in preventing such problems, ensuring that the hydrant remains fully operational when needed.

Detailed Checklist for Maintaining Fire Hydrants

To ensure that fire hydrants remain functional and reliable, it is important to follow a comprehensive maintenance checklist. Below is a detailed guide with actionable steps to help you keep your hydrants in optimal condition:

Inspect the Barrel Regularly

- Check the exterior of the barrel for signs of damage, such as cracks, rust, or dents.

- Ensure that reflective strips or paint are intact and visible. Replace if necessary.

- Verify that the barrel is securely anchored to the ground to prevent tipping or displacement.

Test the Valve Mechanism

- Use a wrench to manually open and close the valve, ensuring smooth operation.

- Look for leaks around the valve when it is open. If detected, investigate further to identify the source.

- Clean the valve and operating stem to remove any accumulated debris or corrosion.

Examine Nozzles and Outlets

- Inspect each nozzle for obstructions or damage. Clear any debris blocking the openings.

- Test the threading on the nozzles to ensure compatibility with standard hose couplings.

- Replace worn or damaged caps or covers to protect the nozzles when not in use.

Check the Water Main Connection

- Confirm that the corporal is securely attached to both the hydrant and the water main.

- Listen for unusual noises or vibrations that may indicate leaks or blockages.

- Coordinate with utility providers to inspect the water main periodically for signs of deterioration.

Evaluate the Internal Components

- Remove the cap and inspect the valve mechanism for signs of wear or corrosion.

- Lubricate moving parts as needed to ensure smooth operation.

- Replace any damaged or defective components promptly to avoid further complications.

Ensure Proper Functionality

- Conduct flow tests to verify that the hydrant delivers water at the expected rate and pressure.

- Record test results and compare them to previous data to identify trends or anomalies.

- Address any issues identified during testing immediately to restore full functionality.

By adhering to this checklist, you can help ensure that your fire hydrants remain ready to respond to emergencies whenever needed. Regular maintenance not only prolongs the lifespan of the hydrant but also enhances its performance, providing peace of mind for both firefighters and the communities they serve.

Deja una respuesta